Hybrid Thermo-Piezo Electric Generator (TPEG) testbed manufactured at SONACA

The testbed for the integration and functional tests of the TPEG is nearing its completion. The testbed represents a section of a slat (leading device on aircraft to increase lift during take-off and landing). The slat is manufactured in composite and incorporates a heating system for deicing purposes.

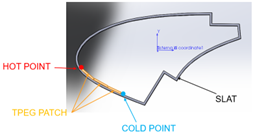

Above a typical slat and a simulated section used for the development of the testbed configuration and design.

The TPEG will generate energy using the vibration developed during the flight, especially during deployment of the slat at take-off and landings and when the de-icing system is activated.

TPEG patch locations at the slat and the testbed. The TPEG patches will be attached to the composite skin which incorporates a heating mat and a series of thermocouples to guarantee a correct heat transfer to the TPEG patch.

Two composite demonstrators loaded into the autoclave for curing and after curing showing the extensive thermocouple network are presented in the pictures below.

The specimens are ready for the next step which will be the integration with the TPEG patches and test performance for validation of the hybrid TPEG concept.