Mechanical recycling of p-type thermoplastic composites of Thermoelectric Generators (TEG)

As a part of the InComEss mission to develop sustainable materials for Thermoelectric Generators (TEG), team experts have achieved promising progress in the mechanical recycling of p -type thermoplastic composites.

Using LEISTRITZ ZSE27 twin-screw extruder, the team conducted a series of recycling cycles on dry polycarbonate (PC) pellets loaded 5 wt% of Multi-Walled Carbon Nanotube (MWCNT) NC7000 composites at vicinity of melting temperature of polycarbonate.

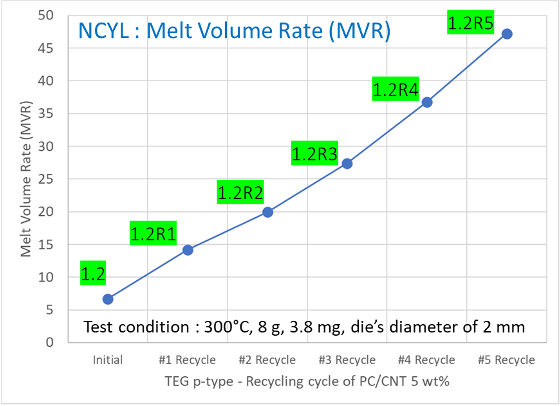

The process involved meticulous control of parameters, including screw profiles, screw speed, throughput, profile temperature of 11 zones inside extruer, die types, and pelletization. Initially, they formed composite PC/5wt%CNT NC7000 pellets, denoted as sample 1.2, through a compounding process. To assess the viability of the recycling process, the researchers embarked on multiple recycling cycles, labelled 1.2R1 to 1.2R5 which corresponds to the first cycle to the fifth cycle, maintaining consistent extruder parameters.

p-type: Recycling results of PC/5wt%CNT NC7000 – sample 1.2

One of the key observations during the recycling cycles was the steady increase in melt volume rate (MVR). Researchers suggest that this rise may be linked to the breakage of polymeric chains and partial damage to the Carbon Nanotube (CNT) network throughout the mechanical recycling cycles.

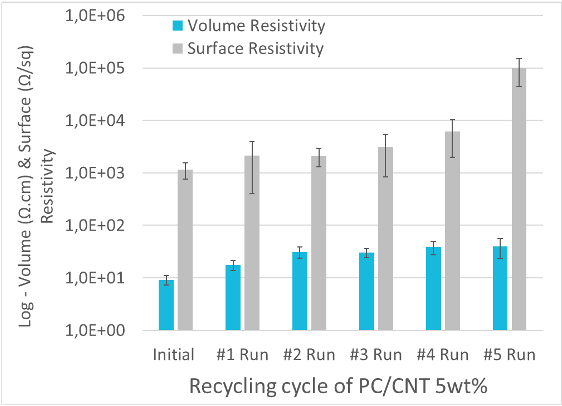

Intriguingly, measurements of surface and volume resistivity (SR/VR) at each cycle revealed that the CNT's network withstands several recycling cycles without significant loss of electrical conductivity. Even after the #4 recycling cycle, where a slight increase in resistivity was noted (less than one order of magnitude), it demonstrated a partial 3D CNT network breakage. The increase in MVR was attributed to both breakage of the CNT network and polymer chains.

By the #5 recycling cycle, both VR (<10E02 Ohm.cm) and SR (<10E05 Ohm/sq) of the samples remained suitable for use in other applications. This suggests that recycled polycarbonate composite PC/CNT NC7000 from the p-type of TEG could find new life in applications such as electrostatic discharge (ESD) or electromagnetic interference shielding (EMI), where stringent mechanical properties are less crucial.